There are two different types of injection systems in the diesel engines or compression ignition (C I Engines). One is the Air Injection System and another one is Airless or Solid Injection System. In this post, we are going to learn about the Common Rail Direct Injection System CRDI System which comes under a solid injection system.

In this post, we are going to focus on only Common Rail Direct Injection System.

Table of Contents

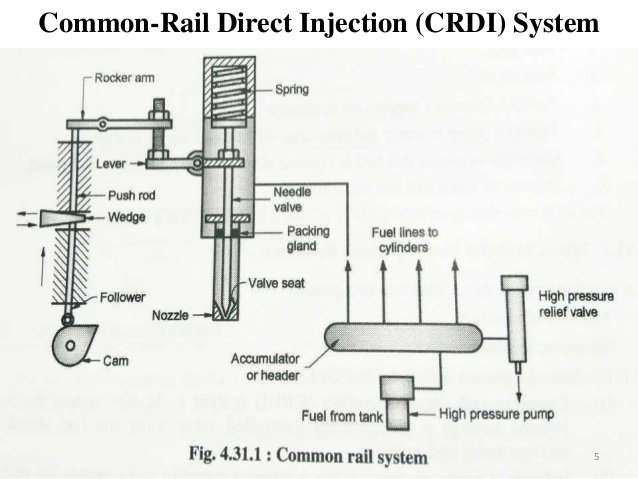

Components in Common Rail Direct Injection System – CRDI System:

- Fuel tank

- Accumulator [Header]

- High-pressure relief valve

- Spring and needle valve

- Cam, follower, rocker arm and lever

- Wedge

- Packing gland

Read About Multi Point Fuel Injection System (MPFI) – Working, advantages

Working of CRDI System or Common Rail Direct Injection:

- As you can see in the diagram of the CRDI system, the high-pressure pump is used to supply fuel to the accumulator or the header from the fuel tank. In case pressure in the accumulator increases beyond the limit, the high-pressure relief valve which is connected to the accumulator helps to reduce the pressure.

- Now, this fuel from the accumulator supplied to engine cylinders using fuel lines with the help of solid injectors.

- Another spring-loaded high-pressure relief valve used to maintain the constant pressure in the system for smooth operations. It also returns the extra fuel of the accumulator to the fuel tank.

- In the diagram, you can see the needle valve. It is used to control the opening and closing of the nozzle while it sprays the fuel into the cylinders. The upward and downward motion of the nozzle is measured by the cam.

- Cam is connected to the spring with the help of a rocker arm and lever. During the dwell period of the cam, spring with the help of the needle valve prevents the injection of the fuel into the cylinder.

- The packing gland ensures the level of the fuel above the valve seat for better injection of the fuel into the cylinders.

- The wedge plays the main role in this system. It controls the amount of fuel to be injected into the cylinder in accordance with the power required for the engine. The wedge is operated by a governor or it can be operated manually as per requirement.

Advantages of CRDI System:

- CRDI system can control the flow of fuel in accordance with the load and speed of the engine.

- This system requires only one fuel pump for multiple cylinders.

- CRDI system is beneficial for the environment as it reduces noise, smoke and particulate matter.

- It gives high power output at low rpm.

- The main advantage of the CRDI system is fuel economy.

Disadvantages of CRDI System:

- This system is complex than MPFI system and needs good engineering work.

- The CRDI system cannot suit ordinary engines.

- The maintenance cost of this system is higher than the others.

- Vehicles with CRDI system is costlier in comparison to non-CRDI system vehicles.

Read About Carter Carburetor: Construction, working and diagram

Vehicles use CRDI system:

Nowadays, all premium or semi-premium vehicles use the CRDI system in their vehicles as it gives more advantages over other vehicles in the market. Following vehicles are using CRDI system:

- Mercedes-Benz all models

- Tata motors

- Hyundai

- Toyota

If you have any queries about this article, please ask it in the comment section.

From which book the above figure is taken, kindly let me know. Thank you